Feedback

Comite de Lesseps

General properties

Physical properties

About this page

Last Updated

History

| Timeframe | Equipment | Manager | Review |

|---|---|---|---|

Review:

--

|

About this equipment

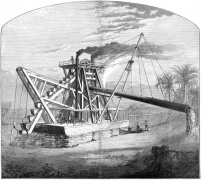

OUR engraving represents one of the great dredgers now in use on the Panama Canal. The contract for the ten miles of marsh work, beginning near Aspinwall, was taken by Slaven Brothers, of this city; the great machine is believed to be the most effective of anything in the same line. It was built under the patents of Messrs. H. B. Angell and H. H. Lynch. The machinery of the dredge is mounted on a scow one hundred feet long, sixty feet wide, and twelve feet deep. There are eight engines, arranged in four pairs, for operating the machinery. The main engines are for driving the buckets which do the digging, and are of 250 horse power, having Myers' adjustable cut-off. The belt from the engine runs to the top of the bucket tower to a pulley eight feet in diameter, which drives compound driving gear, connected with the upper tumbler shaft, which is ten inches in diameter. This shaft moves a thirty-six inch square drum, over which the buckets pass when they dump their load into the hopper. The bucket tower is forty-five feet high above deck. There are thirty-eight buckets, with a capacity of one and a half cubic yards each. From sixteen to eighteen buckets full of dirt per minute are discharged into a hopper attached to a cast iron elbow near the top of the tower. This elbow is five feet four inches in diameter where it connects with the hopper, and thirty-six inches in diameter where it connects at the lower end to the discharge pipe, which is attached to the elbow. This pipe is made of boiler iron and is one hundred and fifty feet long. The distance the mud falls, the position in which it strikes, and the inclination of the discharge pipe give the mud a velocity of from 1,300 to 2,000 feet per minute through the pipe, according to the kind of material which is being dug and discharged. The discharge pipe is supported by a derrick which stands on the scow. Water is pumped into the hopper by a pair of ten inch pumps from the canal through a seven inch pipe which passes through the bottom of the boat and extends to the hopper, at top of bucket tower. A second pair of engines of thirty horse power raise and lower the ladder that supports the buckets; they are attached to a drum for that purpose. There is a hinged joint in the ladder outside of the derrick, for the purpose of operating one section of ladder independent of the other. A half inch cable connects the drum to the outward end of the lower section by two bails. The endless chain to which the buckets are attached is made of horseshoe iron 1-and- 1/8 inches by 9 inches. Another pair of spud and gypsy engines of thirty horse power is used for raising the spuds and feeding the buckets. The dredger rests upon the spud, upon which it can be revolved without stopping the dredging buckets, thus enabling the operators to dig from side to side at will. A chute connects with the hopper, and is boarded on the sides to prevent the mud or water from falling upon the deck. The fourth pair of engines, also of thirty horse power, is connected to a windlass for snag pulling. The engines are all supplied with steam from one set of three boilers, and will require only about two tons of coal each day. Six men, including a superintendent, run the entire machine. Capacity of the dredger, 1,000 cubic yards per hour

Technical files and datasheets

No files available