In the picture: Capt. Henk Klooster

The Dredgepoint database was established in 2008 and is frequented by thousands of people every month. But who are the people behind it and what drives them?

An interview with founder Henk Klooster who also gives his vision on the future of dredging:

DP: Henk, tell us about the origin of Dredgepoint, why the initiative?

Henk: After 20 years of dredging at leading dredging companies I started my own business and realised that I needed a PR machine. At the time there was no professional online database that could be accessed for free. There were some private initiatives like Dredgers.nl from our friend Bert Visser, but I also had the ambition to dig up and map the history of dredging and preserve it for future generations.

DP: What happened then?

Henk: After some research I chose Drupal, which is an open source Content Management System, as the base and got in touch with Thierry Dikstaal from Mingos who is a Drupal expert. Thierry has built the whole site and everything you see and don’t see and maintains it ever since.

DP: How did you get the content?

Henk: We received the database from Dredgers.nl and the company database from DEMAS consultants. Both these databases were then combined and put online. Since then the database is growing and updated every day. We receive an average of 70 emails each week from people all over the world with updates on dredging equipment, changing company details etc. All this information is processed entirely by volunteers.

DP: Who are these volunteers?

Henk: They are mainly retirees who spend their whole life in the dredging industry. For instance first hour Dredgepoint volunteer Bert Lodonk. Bert retired from Boskalis and is also volunteer at the Dredging Museum in Sliedrecht. In the museum library he dug up thousands of historical dredgers and their owners and builders and added al this information to the database. I also would like to mention Frans Lijmbach (retired IHC) and Frits Visscher (retired van Oord)

DP: How about your yourself?

Henk: I retired form Dredgepoint in 2010 (laughs). Well I am kidding off course, but in a way it is true.

I never intended to become an internet entrepreneur and in 2010 I limited my involvement and handed it over to others. Dredgepoint.com was then changed to Dredgepoint.org and since then I focus on my core business.

DP: What is that core business?

Henk: (thinks) Innovation in dredging is what comes up to describe that core. Innovation is the key in everything I do. Regardless if I am involved in a dredging, engineering or newbuilding project my brain is always scanning for improvement. And yes, sometimes I get tired of myself (laughs)

DP: Why is Innovation so important?

Henk: The world is constantly changing and so is the dredging world. In 1970 there were 64 different dredging companies in The Netherlands and Belgium. Today there are only 4 large enterprises remaining and a handful of smaller companies. In 1990 the larges TSHD had a hopper capacity of less than 11,000 m³ while today the largest hopper dredgers can carry 46,000 m³, this requires a lot of innovation. The modern dredgers itself cannot be compared to the dredgers in the old days. Simultaneously, where in the old days youngsters usually were prepared for a certain discipline in several years of tutoring, in today’s fast expanding fleets there is often no time for such. An answer can be to make the dredgers itself intelligent. In other words; more innovation.

DP: How does the future of dredging look like?

Henk: I don’t have a crystal ball off course, but I can see some changes coming. The big dredging companies have already spread their wings into Offshore and Energy and I think that this will further expand to offshore mining. Western dredging companies will have to keep up the high tech, while new dredging companies will emerge in Asia, China in particular, who are spreading their wings to global dredging. Natural resources on shore are getting scares and increasingly harder to mine and therefore more expensive to mine. This opens the door to offshore mining, for instance dredging of methane ice, manganese and diamonds. This is already going on.

Also, it is common knowledge that the oil reserves are not endless. The scale enlargement of dredging equipment also meant an enlargement of total installed power with proportional fuel consumption and emission. Dredging companies will therefore have to look for ways of making their dredgers greener and more fuel efficient. The use of Artificial Intelligence and alternative fuel could be an answer for the medium term.

DP: I think this needs some explanation

Henk: I was recently part of a study group that looked at LNG as an alternative fuel for dredgers.

LNG will definitely make a dredger greener, but the present infrastructure is limited.

From a technical point of view dredging on LNG is no problem, but most commercial dredging companies are world players who are often working in remote areas. As long as a good global LNG infrastructure is not there it will not be practical. The same applies to other alternative fuels while

nuclear fusion is still decades away. Fuel efficiency will therefore be the key. Look for instance at VOLVO cars: in 1980 1 litre of fuel would take their cars only 7 or 8 kilometres further, while today this is nearly 50 kilometres.

DP: And Artificial Intelligence?

Henk: I know this sounds futuristic, so let s call it self-learning software like in today’s self-diagnostic cars. Dredgers are build up from many stand-alone pieces of equipment. All the equipment combined gives a certain result, yet most of the equipment is not talking to each other and the overview lies in the hands of people. I predict that in the future AI systems will result in a fuel reduction up to 20% with the same installation, simply by making individual components intelligent, connecting them and add a self-learning system that has the overview. This is already common good in other industries and dredging will follow sooner or later.

In 2011/2012 we already laid the base for this by developing a Mechatronic dredger automation system. Currently we are developing the first intelligent components.

DP: Can you give an example?

Henk: (thinks) Look for instance at the draghead from a trailing suction hopper dredger. It is literally being dragged over the ground. Overcoming the drag forces requires propulsion power which immediately translates into fuel use. By designing the draghead so that the friction between the draghead and the soil is minimal the first step is made. Again we can take the automotive industry as an example who carefully looks into aero dynamics to make their cars fuel efficient. Next, and this is where intelligence kicks in, the swell compensator of the draghead not only compensates for swell, but by increasing or decreasing its pressure it can also regulate the friction between the draghead and the soil. Self-learning software can find the optimal pressure, but it has to be able to talk to the propulsion and the dredging installation in order to find that optimal pressure. To save on fuel consumption all a TSHD owner has to do is change the dragheads for a fuel efficient design and add some intelligent software. Also environment is getting increasingly important and tightening emission rules will force into taking steps.

DP: So you are an inventor?

Henk: Inventor is loaded, it recalls images of a crazy professor inventing something beyond imagination shouting eureka. Innovation does not work that way. It is a process that is usually triggered by a simple question: how can we improve this? Look for instance at the sand motor. Every year millions of cubic metres of sand disappear from the Dutch coast and have to be replenished by dredgers. Engineers came up with the idea of an artificial island off the coast. Wind, waves and currents are now spreading the sand naturally which is called ‘Building with Nature’. The people who invented this are no crazy professors but brilliant engineers that showed ingenuity and dared to look out of the box. I like that. However, a lot of people are more comfortable with old problems than new solutions, that is the burden of innovators.(grins)

DP: Can you tell us something about your work?

Henk: I am a consultant, I limited it to dredging alone, but in a wide variety of works.

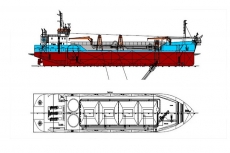

Sometimes I am hired to solve problems on dredgers or on a dredging project, sometimes I am involved with engineering, dredger design, new building, modifications or major conversions.

I am also hired for inspections and assessments of dredgers for instance prior to purchase or charter or to make an investment plan for improvement. I am also hired by offshore companies for trenches and cable laying. Apart from that I have invested a lot in new dredging techniques, dredger design and intelligent dredging components and although I keep learning every day, there is still a lot to discover out there.

DP: What did you discover on Dredgepoint?

Henk: (laughs) I find a lot of information in the Dredgepoint database, for instance that the world’s dredger fleet is aging and in some categories are already beyond the economic life span. Good news for dredger builders that is. Overall, there is more good news for dredging companies, the expanding world population will settle in coastal areas which requires infrastructure and land reclamation, while simultaneously the sea level rises due to the greenhouse effect. A golden future.

DP: And the future of Dredgepoint?

Henk: As you know we have plenty ideas on how we can expand the services on Dredgepoint, like jobs and news, but developing new modules requires investments. So far I am still the major sponsor of Dredgepoint simply because no other sponsors knocked on our door yet. Perhaps its value is underestimated, Dredgepoint is a unique worldwide platform that reaches tens of thousands of visitors from a very specific target group every month. I realise that our historical information may have little value for commercial companies, but to understand the present, you have to know the past.

And due to the open source structure and the worldwide feedback from our visitors the quality of the actual information is better than in any other dredger databases and we are proud of that.

Furthermore we are looking into ways of turning Dredgepoint into a foundation, but this is easier said than done. But in time we hope to get there.

DP: Any last words for the readers?

Henk: I want to take this opportunity to say thank you to all the visitors who keep sending us feedback on dredging equipment and many thanks to all the volunteers for their effort and input. Also I would like to encourage companies and professionals to subscribe to a paid account. This would really help us to keep up the good work and provides access to professional features in order to get much more out of this unique database.

Master Mariner and former TSHD Captain Henk Klooster is Managing Director and Consultant at Dredge Vision Consultants BV. www.dredgevision.nl